Technology

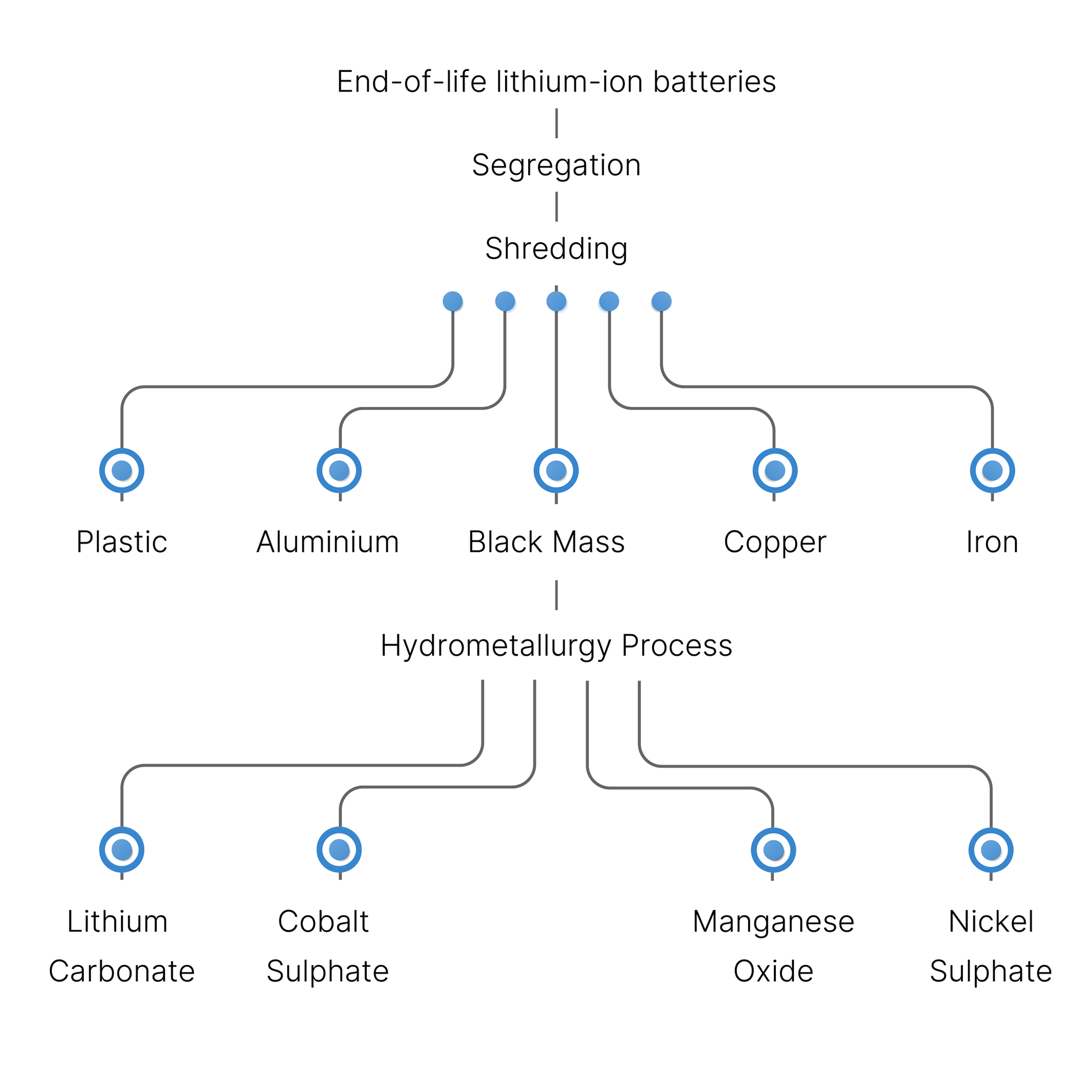

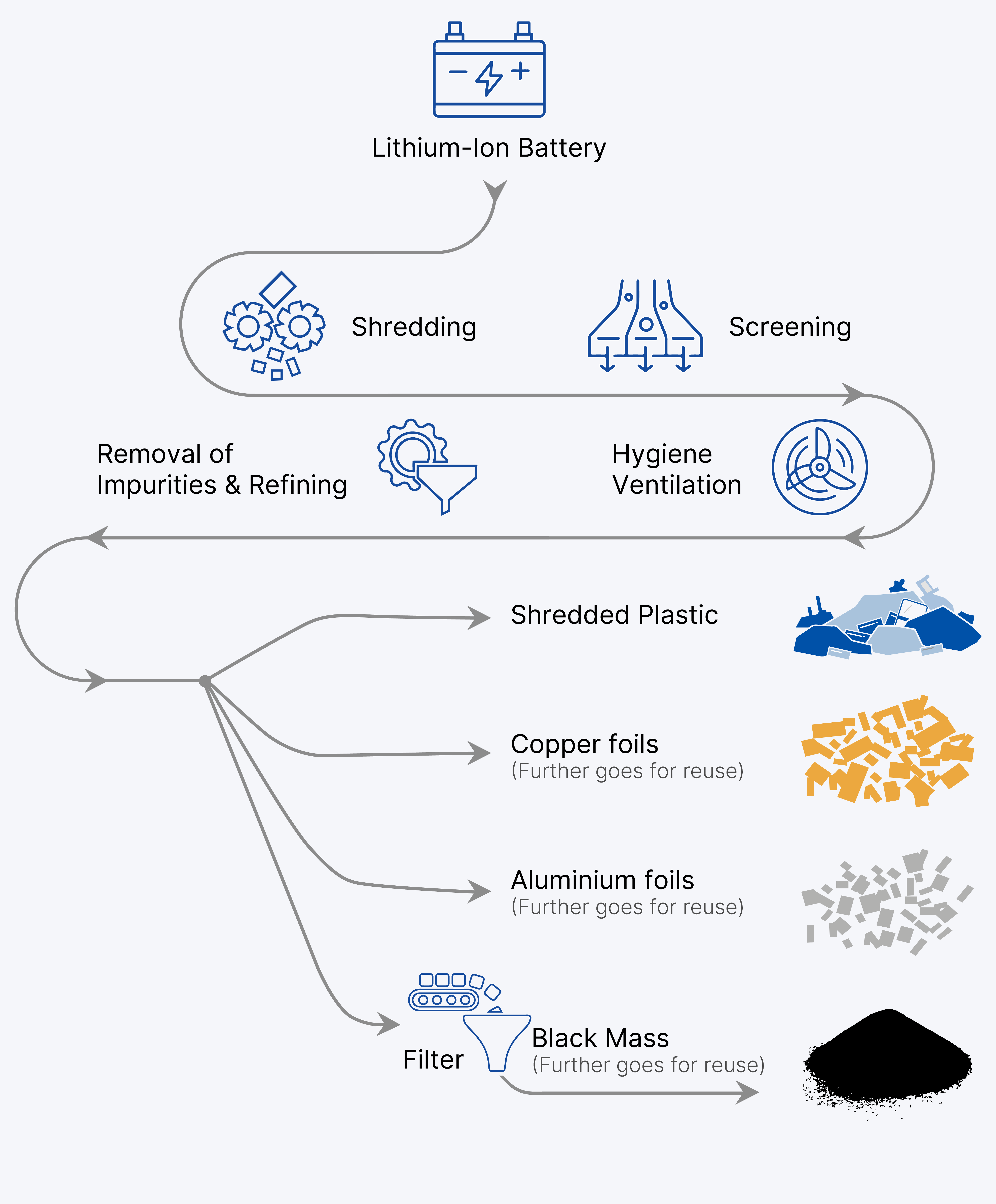

LICO uses a mechanical shredding process where spent lithium-ion batteries are shredded and crushed into fine sizing. Magnetic separation, vibration screens and multiple sieving techniques will separate the plastic, steel, aluminium foil, copper foil and black mass. This process ensures zero waste and zero discharge supporting eco-friendly recycling, thus, recovering everything from the spent batteries and having zero losses of critical materials or battery waste.

The black mass is treated using a proprietary hydrometallurgy process to separate compounds of Lithium, Cobalt, Nickel and Manganese with an industry comparable high recovery rate and high purity for these metals. The recovered compounds and battery raw materials are supplied back to a lithium-ion battery or cell manufacturer so that they can be used for a second life.

Operational Process

Products

The products derived from our proprietary Recycling Process:

COPPER

ALUMINIUM

BLACK MASS

MANGANESE OXIDE

NICKEL SULPHATE

LITHIUM CARBONATE

COBALT SULPHATE