Technology

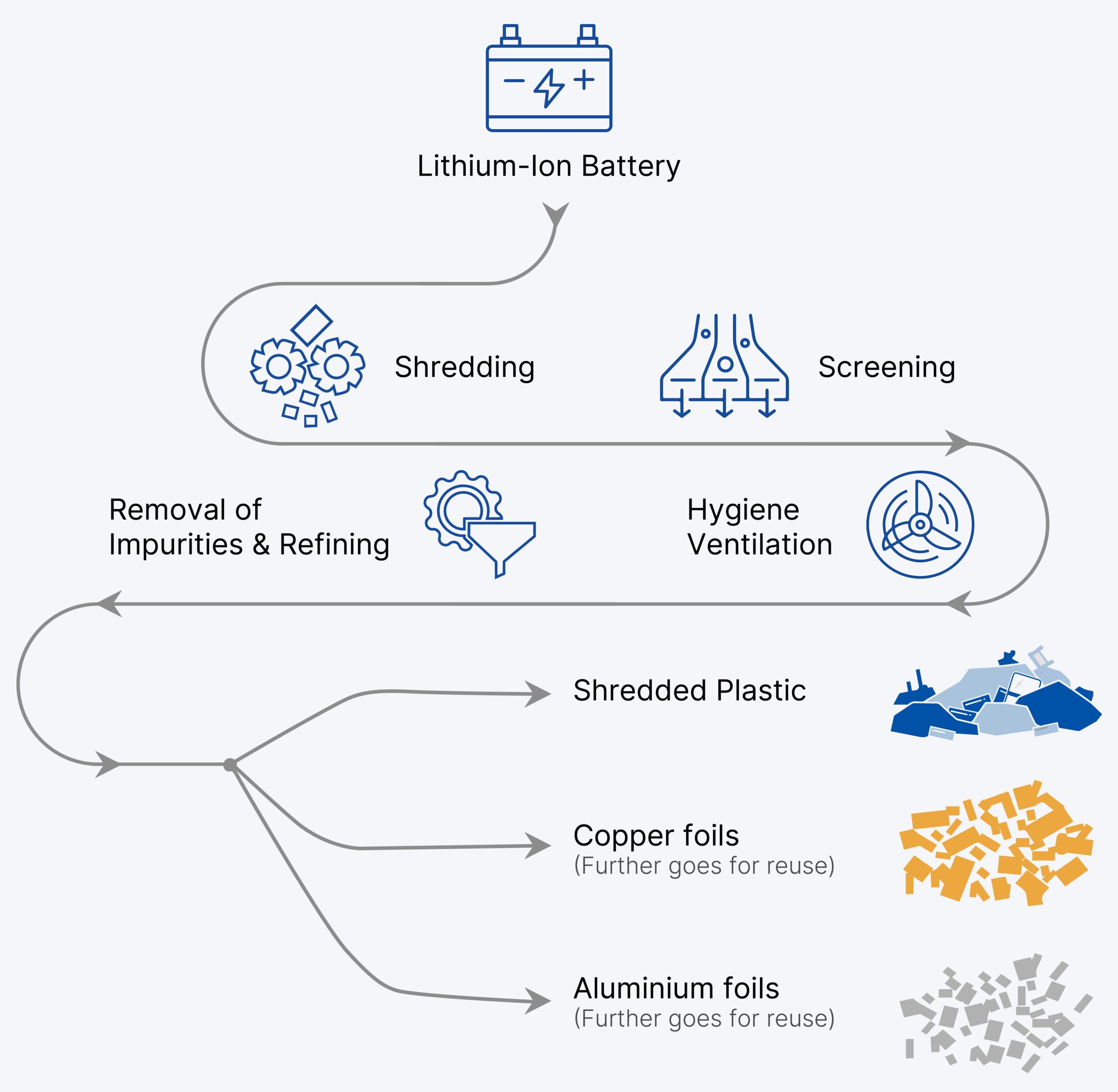

LICO uses a mechanical shredding process where scraped lithium-ion batteries are shredded and crushed into fine sizing. Magnetic separation, vibration screens and multiple sieving techniques are used to separate plastic, steel, aluminum foil, and copper foil. This process ensures zero waste and zero discharge supporting eco-friendly recycling, thus, recovering everything from the spent batteries. The global industry standard Recovery Rate from mechanical separation is at 75-80% but at LICO, we have achieved recovery rate as high as 92% in our mechanical separation process.

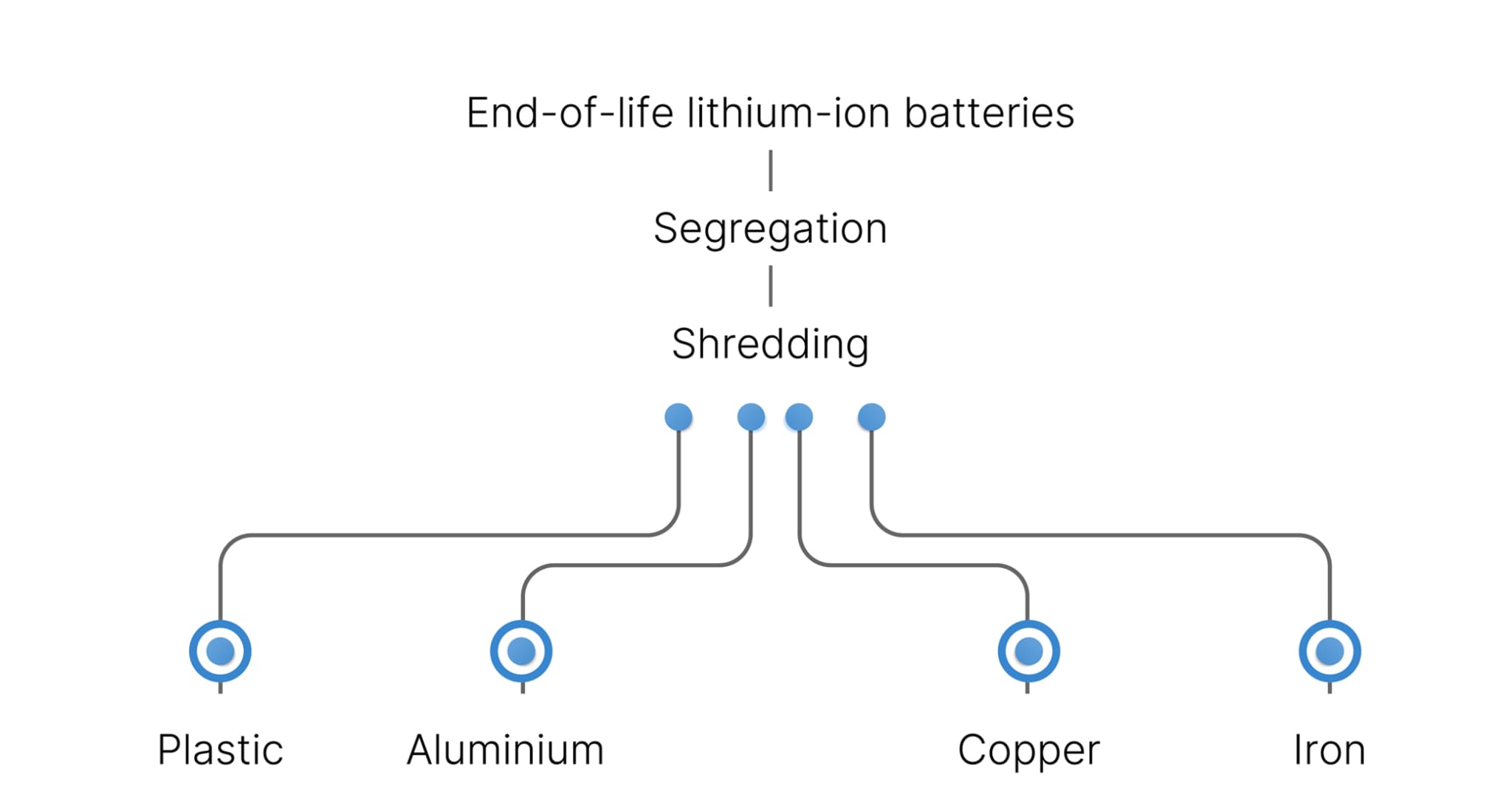

Operational Process

Products

The products derived from our proprietary Recycling Process:

COPPER

ALUMINIUM

The products derived from the Chemical Refining Process are:

MANGANESE OXIDE

NICKEL SULPHATE

LITHIUM CARBONATE

COBALT SULPHATE